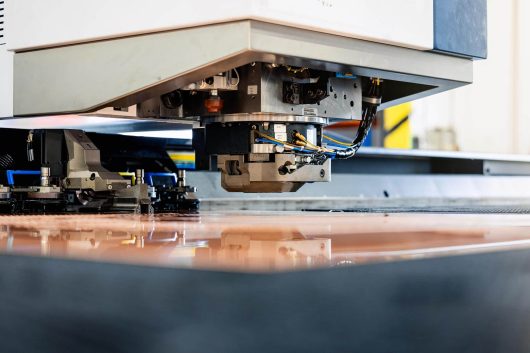

Our suite of turret presses allow us to efficiently and precisely punch holes, shapes, and profiles into perforated products. It also allows the production of image perf, where perforated sheets are designed and punched to provide a visual interest whilst still offering functionality such as ventilation or shading.

Advantages of using a turret include high precision tight tolerances, fast production, low production volumes and prototyping flexibility. Industries such as fabrication, architectural, automotive, yellow goods and electrical enclosures all benefit from our turret press capability.

Degreasing perforated sheets is essential for cleanliness, maintenance, hygiene, performance, and safety in various industrial and commercial applications.

Across industries, degreasing is used to ensure quality, cleanliness and performance. For food processing it is essential to prevent contamination of food products and maintain hygiene standard. With Aerospace it is essential to maintain cleanliness and prevent contamination in sensitive aerospace environments. For pharmaceuticals it helps to ensure product purity, and in HVAC it helps maintain air flow efficiencies and prevent contamination of indoor air.

Other industries that benefit from degreased perforated sheets include, construction, automotive and electrical enclosures.

Rather than having to deal with multiple suppliers, we can provide additional services to your perforated components. Along side our in house facilities we work with our established team of subcontractors providing finished products that can be painted, powder coated or anodised, tailored to your specific needs.

We look to work with our customers as a partner, so if you have a specific application, whether its for architectural, automotive, industrial or decorative purposes give us a call to see how we can help.